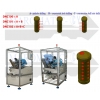

DNC100, DNC101, DNC102 -Pinhole Drilling (1 direction)

Technical data

- Control System: HMI and PLC/PC

- Screen Display: machine commands, error codes, trouble shooting guide, and production statistics on HMI screen

- Machine Size (approx.): 100 cm x 65 cm x 210 cm

- Machine Weight (approx.): 550 kg

- Power supply: 3 phase 220V

- Air pressure: 6 bar

- Cycle time: 8 sec/ 1 part (for 5 holes)

Products

- DNC100 machines drill pin holes only using a single spindle on a servo controlled slide.

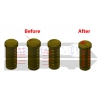

- DNC101 machines drill pin holes using a single spindle on a servo controlled slide. A second spindle drills the counter sink hole for the key.

- DNC102 machines drill pin holes and construction holes using two spindles on a servo controlled slides. A third spindle drills the counter sink hole for the key.

Either a feeder bowl or a magazine automatically feeds the parts for all three models.

Bowl feeder or magazine loading could be chosen for loading the barrel. This machine only has one drilling unit for pinhole drilling. And it is servo controlled. The pitch of the pinhole could be adjusted. It takes a little more time due to drilling the pinholes one by one. You also can add the 2nd drilling unit (DNC105)for the countersink hole drilling. It will make the key inserting into the keyway easily with this hole. The 3rd drilling unit with servo mechanism could be added also. It is the DNC110. It will have the function to drill the construction ball holes.